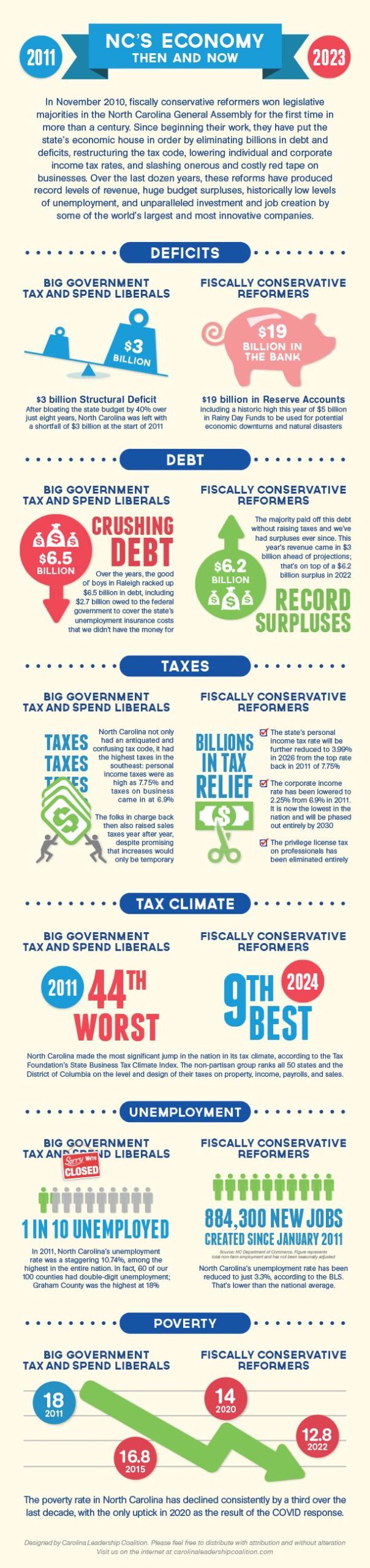

Yesterday, Boom Supersonic announced major milestones across its Overture airliner and Symphony engine programs at the Farnborough International Airshow in the United Kingdom. In January 2022, Boom announced that they were building a jet manufacturing and assembly facility in Greensboro. This “super factory” will employ as many as 2,400 people to build their Overture supersonic airliners — which fly at nearly twice the speed of sound on 100% sustainable aviation fuel — for commercial service. The company finished the facility in June of this year.

Boom unveiled an all-new flight deck for Overture, designed around pilots with safety at the forefront. The next-generation flight deck builds upon years of learning in aviation safety and is the result of extensive feedback from airline, business, and military pilots.

Boom also demonstrated rapid progress on its Symphony engine, with hardware testing underway and the first full-scale engine core to be operational in just 18 months. Additionally, Boom announced its full production plan for Symphony, expanding its relationship with StandardAero to include engine assembly and testing at their facility in San Antonio, Texas.

“Passengers and airlines are hungry for supersonic flight,” said Blake Scholl, founder and CEO of Boom Supersonic. “Following XB-1’s successful test flight, we’re accelerating. Overture features an all-new flight deck, incorporating extensive pilot feedback, resulting in a flying experience that is both innovative and instantly familiar. Our Symphony engine has quickly progressed through design into hardware rig testing, and with a fully operational engine core on track for next year, our rapid development approach is pacing ahead of schedule.”

Boom continues to partner with airlines and best-in-class industry suppliers, announcing today that ATI had joined the Symphony program, while Universal Avionics is coming onboard to support Honeywell on Overture’s flight deck. Boom also worked with BAE Systems to integrate Active Control Sidesticks into the Overture flight deck simulator displayed at the Farnborough International Airshow.

In March, the company conducted the historic first flight of its XB-1 supersonic demonstrator.

Update from August 26, 2024: Boom Supersonic successfully completes more tests

Boom Reinvents the Cockpit

Anchored by the Honeywell Anthem avionics suite, Overture’s flight deck combines state-of-the-art technologies with safety-enhancing features to give pilots unprecedented situational awareness and ease of control.

Boom’s flight deck delivers the benefits of advanced automation and envelope protection, together with a force-feedback system that allows pilots to feel how the airplane is flying. With key airplane features accessible through high-definition touch screens, Overture can benefit from ongoing over-the-air software upgrades.

- Force-feedback sidesticks. For the first time on an airliner, force-feedback sidesticks allow pilots to control the plane while physically feeling both aircraft response and inputs made by the co-pilot or autopilot

- Autoland and augmented reality. Building on the system flown on XB-1, Overture has an advanced augmented reality vision system for takeoff and landing, eliminating the need for the droop nose used on Concorde. Pilots can safely land using autoland or augmented reality views provided on a headworn device and on the pilot’s primary flight display

- Large 17-inch touchscreens. High-definition touchscreens eliminate the hundreds of breakers and buttons found in legacy cockpits. Every airplane function is accessible through software while physical controls—such as stick, throttle, and landing gear—are offered for safety-critical functions

- Over-the-air upgrades. Overture will receive over-the-air software upgrades, meaning new features and improvements will arrive regularly. Airlines can control how upgrades are rolled out across fleets

For takeoff and landing, Overture pilots will use Universal Avionics’ SkyLens II head-worn device, which integrates multiple camera views (synthetic and natural vision) together with key flight data to provide a centralized view of all essential information. By combining multiple cameras and sensors, the system uses augmented reality to expand the pilot’s acuity of the real-world environment, providing enhanced situational awareness and passenger safety.

“We are excited to enter into this partnership with Boom Supersonic, bringing years of innovation in Enhanced Flight Vision Systems to Overture,” said Dror Yahav, Chief Executive Officer at Universal Avionics. “Driven by the need for supersonic travel, the unique shape of this aircraft and advanced operations benefit from the full breadth of ClearVision, from the latest generation of Head-Wearable Displays to certified image fusion and augmented reality applications.”

Airline Pilots Fly Overture

Boom has been working with airline, business, and military pilots to develop the all-new flight deck for Overture. Boom recently completed a series of flight deck tests with commercial pilots from leading airlines, and Mike Bannister, former Chief Concorde Pilot for British Airways. The flight path included a supersonic cruise over the Atlantic and an approach into Heathrow.

“I’ve long believed that Overture is the rightful successor to Concorde,” said Mike Bannister, former Chief Concorde Pilot for British Airways. “After experiencing Overture’s flight deck, which is incredibly well designed and delightful to fly, my excitement and enthusiasm for this aircraft has only intensified.”

Rapid Development Approach for Symphony Engine

In June, Boom revealed that it is already building and rig-testing Symphony hardware, starting with a full-scale test of combustor aerodynamics. The first 3D-printed parts have been produced for Symphony, including fuel nozzles and turbine center frames.

These hardware tests began just 18 months after the initial announcement of Symphony, demonstrating our rapid development approach. As part of this strategy, the company will conduct more than 30 engine hardware rig tests, allowing for validation and optimization of all key engine components, ranging from fan and nozzle acoustics to combustor fuel efficiency.

Learn more about the importance of rig testing from the Senior Vice President of Symphony, Scott Powell, here.

Boom also announced that it has accelerated development of a full-scale engine core, which will be operational in late 2025. Testing conducted on the engine core will analyze performance of the compressor, combustor, and turbine section. Data gathered will further refine engineering and expedite production of a fully certified engine. Following this rapid development approach, Boom expects to build and test multiple iterations before certifying the final refined engine.

Boom is working with engine design partner Florida Turbine Technologies (FTT) to execute rig testing and the development of Symphony’s engine core.

“Kratos and our Florida Turbine Technologies (FTT) subsidiary are proud to be the engine design team for Symphony. Designing a sustainable, cost-efficient engine for Overture is a career highlight for us, and we continue to make significant, rapid progress on Symphony including critical engine rig testing,” said Stacey Rock, President, Turbine Technologies at Kratos. “We are on schedule as we pursue critical component rigs for compressors, combustors, and bearings and are developing a “Sprint Core” engine demonstrator that will provide valuable confirmation of engine component performance prior to finalizing the engine design. We look forward to the future and working with Boom to make sustainable supersonic travel a reality.”

Boom also expanded its existing MRO partnership with StandardAero to include the production of Symphony. StandardAero will assemble and test Symphony engines at its facility in San Antonio, Texas. The Symphony production line will scale to produce 330 engines annually within a footprint projected to total over 100,000 square feet of production space.

“We are excited to expand our role to include the assembly and testing of Symphony engines, further supporting the development of next-generation flight with Boom,” said Russell Ford, Chairman and CEO of StandardAero. “Our collaboration is a testament to StandardAero’s world-class engineering capabilities and dedication to delivering solutions that power the future of air travel.”

Additionally, Boom announced it is teaming with aerospace leader ATI, Inc. for advanced high-temperature materials and components for Symphony’s high pressure compressor integrated blade and disk stages and for its turbine assembly. These advanced nickel-based superalloys will enable Symphony to achieve high performance and reliability in sustained supersonic operation.